Roll Sticker

Roll stickers are an excellent choice when fast and efficient label application is needed on a production line or packaging.

When is a roll sticker the best option?

The main advantage of roll stickers is often their automatic placement on the production line using an applicator, which efficiently attaches the stickers to products or packaging. They can also be part of manual labeling machines used, for example, for marking the sides of boxes on pallets. Roll stickers are produced with various rolling options and core sizes, and they can be either paper or plastic.

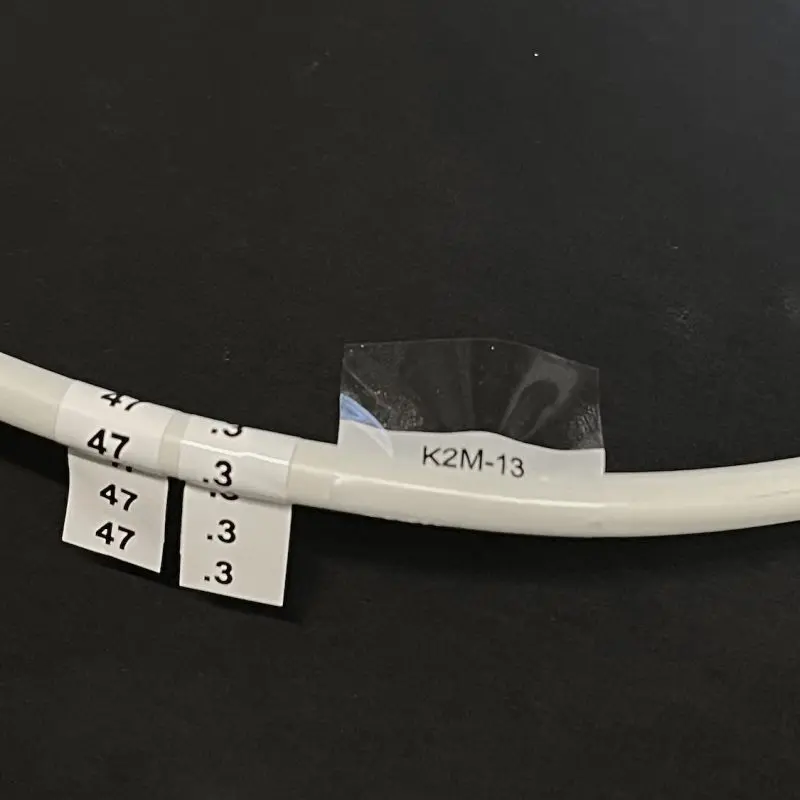

Roll Stickers for Your Own Printing

It is also possible to produce roll stickers with just pre-printing or blank, so the product information can be printed later with the customer’s own printer. These roll stickers are delivered either for thermal transfer printing (where the color is transferred from a ribbon to the sticker) or direct thermal printing (where the film darkens under heat).

What Types of Roll Stickers Can You Order from Tarra-Tac?

PP Sticker (Polypropylene):

The operating temperature for polypropylene ranges between -30°C and +90°C, depending on the grade. PP can be melted and reused or burned as an energy source.

PE Sticker (Polyethylene):

Polyethylene is the most affordable and widely used plastic in the world. It has good chemical resistance, except to strong acids. Most plastic containers are made of PE. When using polyethylene as an adhesive surface, a special adhesive is required because the surface of PE plastic is slippery. The operating temperature ranges between -30°C and +80°C, depending on the grade. We also produce BS5609 certified stickers from this material for maritime use.

PVC Sticker (Polyvinyl Chloride):

The main advantage of PVC stickers is their superior UV resistance. Vinyl stickers are used when a long lifespan is required, and they are exposed to the elements. When the adhesive surface is irregular, it is advisable to use vinyl stickers as they are the most flexible among plastics. The operating temperature range for PVC stickers is between -40°C and +110°C, depending on the grade.

PES Sticker (Polyester):

We produce polyester stickers when a tough plastic is required with high heat resistance. The operating temperature ranges between -40°C and +225°C, depending on the grade. The advantage of polyester stickers is their minimal thermal expansion or contraction. We also offer silver polyester stickers (3M 7983), whose matte silver surface is ideal for machine labeling solutions. Additionally, the surface of the silver polyester has a coating that allows for marking with a pen.

PU Sticker (Polyurethane):

A highly flexible plastic material suitable for applications with an operating temperature range of -40°C to +80°C.

PVC-Free Stickers:

For certain applications where fire regulations prohibit the use of vinyl, we manufacture stickers using PVC-free films.